Give employee safety top priority

The safety of your colleagues rely on whether you are prepared for the unfortunate moment that hopefully never occurs.

An emergency shower can make a big difference when disaster strikes. First of all, the shower helps stop the accident immediately. Second, it provides the quick and thorough rinsing that is needed to mitigate the consequences of the accident.

Improve employee safety with reliable emergency shower systems

Setting the standard

We have manufactured high quality emergency solutions for decades and have become the quality benchmark in the market.

Chosen by responsible companies

Hundreds of top-class companies with focus on employee safety have chosen BROEN-LAB for their shower systems.

Complies with all standards

All safety solutions from BROEN-LAB comply with European (EN) and U.S. standards (ANSI).

Are you ready when the next accident happens?

Are you equipped and ready?

Damage control is an essential part of your safety plan. Especially in workplaces where people handle acids or risk exposure to heat, hazardous material etc.

BROEN-LAB offers a complete range of emergency shower systems tailored to your business need and designed to treat body, face and eyes quickly and efficiently.

All solutions are all in full compliance with international standards and are preferred by leading companies in the pharmaceutical and petrochemical industries, schools, universities and manufacturing companies.

What are the risks in your workplace?

When your employees handle hot, acidic or otherwise hazardous substances, the risks involved are obvious.

But there are other more subtle risk factors in many workplaces.

By considering the following questions, you get an overall picture of the risc scenario,

you have to deal with. And consequently, the emergency shower solution you need.

1 Which hazards are present?

The safety system must match the scope and intensity of the hazards present. For instance, if an accident involving strong acids or caustics can occur, emergency showers should be immediately available. Outside showers should be heated and insulated, if temperatures can go low.

2 Are the hazards permanent or temporary?

Permanent hazards are often found in laboratories, warehouses, production facilities and kitchens. But accidents may as well occur during transportation of people and substances, so the safety measures should also include these temporary danger zones.

3 How many people are present?

Another important factor to consider is the number of people that could potentially be affected by an accident. If, in case of a major emergency, several employees could get injured simultaneously, one shower may prove insufficient.

4 Are injuries likely to be partial or full-body?

Partial injuries are common in laboratories and kitchens, where the hands, eyes and face can be exposed to harmful substances. Full-body damage are more likely to occur in warehouses and production facilities, where quantities are large and accidents can be extensive and impactful.

Improve safety with high quality systems

We offer a full range of emergency showers and accessories, which can be combined to match any safety need. Click to learn more.

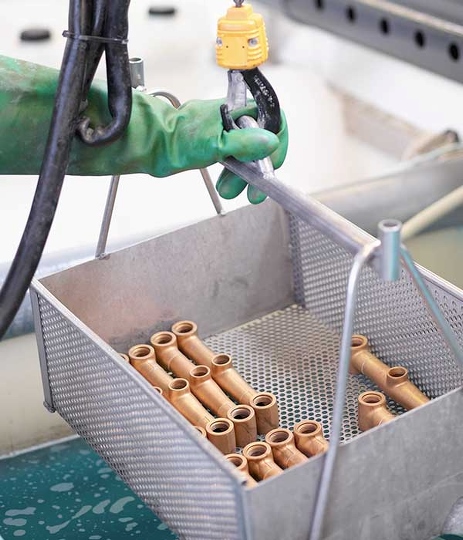

Quality from start to finish

BROEN-LAB emergency shower systems have the following benefits:

- The shower heads always provide the correct water distribution

- Our emergency showers are intuitively easy to operate

- Signage is clear and easy to understand

- The shower heads are self-draining to avoid unclean water and lime deposits

- The material and assembly is of the best quality

- Assembly, service and replacement is easy and cost-efficient

Your safety partner all the way

With BROEN-LAB you get total solutions that cover all your needs from A to Z.

We help you assess the right locations and configuration of your emergency showers,

and we offer expert advice regarding installation, operation and maintenance.

Risk assessment of your workplaces

Our experts analyze your facilities and work flows to determine the various risk factors.

Recommendations for the optimum solution

Founded on the assessment, we design the solution that ensures the optimum level of safety. The recommendation is so specific, it can be used as a requirements specification for all locations in your company. We call it “One Standard”, and this makes it easy to establish the same safety standard everywhere.

Installation and instruction

Our installation team mounts the solution according to our high standards to ensure full security and quality. After installation we instruct your employees in what to do in case of an emergency.

Service and upgrading

Many of our customers sign up for a Total Service Agreement that includes:

- Periodic safety checks on equipment

- Maintenance and repairs

- Upgrading according to EN 15154 1+2 and ANSI Z358:1

- Documentation and status reports

We are ready to guide you!

If you have any questions or want to receive a free quote, please fill out the form below and one of our experts will contact you. You can also contatct us by phone.